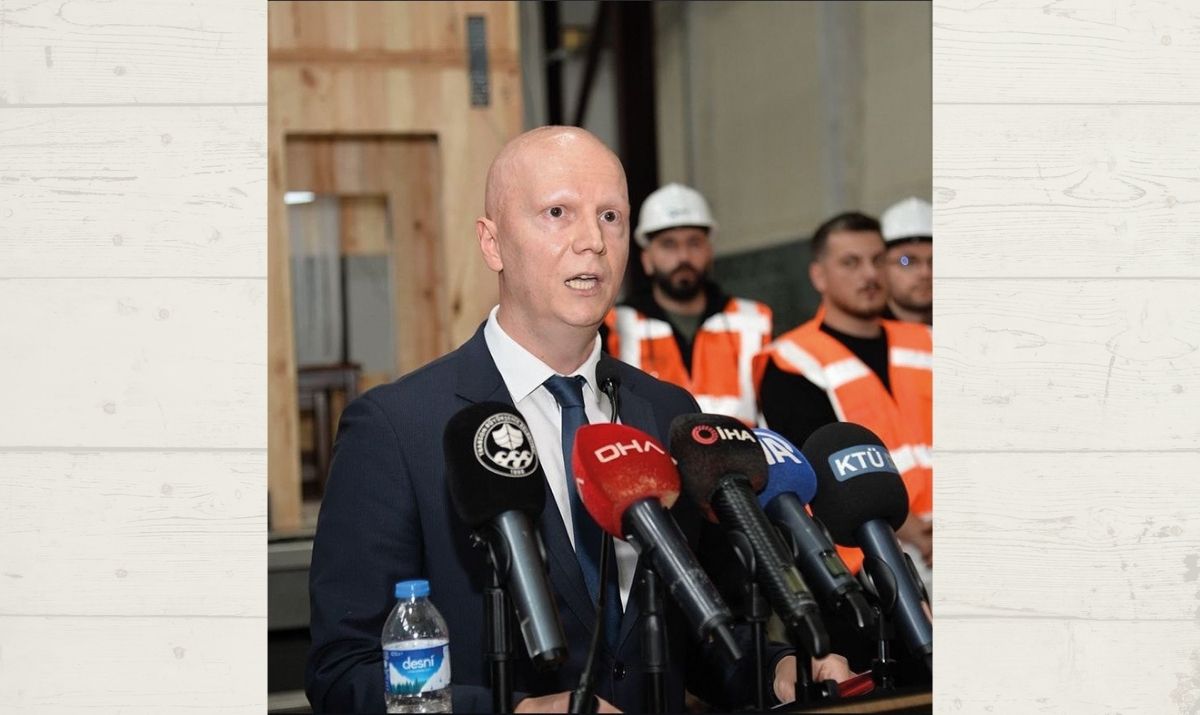

Seen as the building material of the future with its earthquake resistance, low carbon emission and energy efficiency, wood proved its success in earthquake tests conducted with domestic resources for the first time in Türkiye. Karadeniz Technical University Faculty of Forestry, Forestry Industry Engineering – Prof. Dr. Cenk Demirkır evaluated the innovations brought by wooden structures to the construction sector, the important steps taken in sustainable architecture with Türkiye’s first wooden building regulation and the place of this transformation in global architecture.

The modern world is trying to strike a delicate balance between technological progress and nature conservation. The building industry has started to develop innovative and sustainable solutions to achieve this balance. Timber structures have emerged as the building material of the future with advantages such as energy efficiency, low carbon emissions and earthquake resistance. The success of the first earthquake tests conducted with structural timber materials proves that this innovative material is an ideal solution for safe and environmentally friendly structures. Evaluating this new revolution in the building sector, Karadeniz Technical University Faculty of Forestry, Forest Industrial Engineering – Prof. Dr. Cenk Demirkır stated that wooden structures stand out as the building material of the future not only with their environmental friendliness but also with their earthquake resistance and energy efficiency.

- While the world is modernizing, many steps are being taken to protect the planet. In this sense, we see a serious shift towards natural materials in architecture. How would you evaluate this issue?

At the moment, especially with the fight against climate change and the impact of the recent earthquakes, people living in safe structures, protecting nature and revitalizing the construction sector with recyclable and renewable materials are among the most important issues on the agenda. I characterize this situation as follows; a revolution is taking place in the construction industry and our country needs to benefit from this revolution as quickly as possible and follow the developments closely. As a country with a wooden architectural culture, we have moved away from this culture for various reasons such as fire risk, decay, material shortages and the influence of the reinforced concrete lobby. At the point we have reached today, countries such as Europe and America have implemented their own timber construction policies, incentives and legal regulations. Türkiye needs to be a part of this process and follow the developments closely in order to make the most of this revolution in the building industry.

“General Directorate of Forestry converts its own buildings into wooden structures”

- Wooden construction is actually a part of our culture and is not alien to us. However, over time, for various reasons, reinforced concrete systems were used. Is Türkiye currently aware of the situation and is it taking concrete steps in this regard?

Actually, this issue needs to be addressed as follows; how aware are our people of this issue? How aware are our institutions? And how aware is the academic and scientific community? First of all, let’s go backwards and start with the scientific community. I am a faculty member in the department of forest industrial engineering and I have been working on wooden structures and structural wood materials since 2012. However, in the last two years, we see that there has been a serious awareness of this issue not only in forest industrial engineering but also in different disciplines such as civil engineering, industrial engineering and architecture. In these fields, both the inclusion of wood-related content in curricula and the use of wood structures and structural wood materials in new projects are increasingly on the agenda. This is a pleasing development from a scientific point of view. When we look at public institutions, Türkiye’s first “Wood Construction Regulation” entered into force in January 2025. Previously, there was no national regulation on wood; construction was carried out only with reference to European standards. This regulation was prepared as a result of one year of joint work by departments such as civil engineering, architecture, forest industry engineering, NGOs and public institutions. This was a very important beginning for the sector. The General Directorate of Forestry has also taken an important step in this regard. In 2023, within the scope of a European Union project initiated in 2023, work was carried out to popularize the use of wood and promote low-cost, energy-efficient wooden buildings. In addition, after the Kahramanmaraş earthquake, the General Directorate of Forestry decided to convert its own buildings into wooden structures. In this context, constructions started to be realized with both innovative materials and traditional wooden building systems. An estimated 15-20 thousand square meters of wooden buildings were built. This is another pleasing development.

Especially after the recent Kahramanmaraş earthquake, the Ministry of Environment, Urbanization and Climate Change has initiated efforts to develop alternative construction systems to concrete in earthquake zones. We also took part in these efforts, which were carried out in collaboration with civil engineers, industrial engineers and architects. A section called “New Construction Systems” was opened on the website of the Ministry’s General Directorate of Construction Works. This section includes information on five types of building systems that can be used in earthquake zones and the materials to be used in these systems. Reports containing the results of mechanical, physical and structural tests can be accessed. Within this, it is possible to reach a form that includes innovative and new generation wood materials. This shows that the issue is being taken more and more seriously and that there will be faster developments in this field in the coming period.

When we look at the awareness of the public, we see that there is not yet a sufficient level of awareness. People have some prejudices about wood from the past. For example; questions such as “Does wood burn, does it rot, can high-rise buildings be built, will it be durable?” are still common in society. Although these questions have been technically solved, awareness has not yet reached the desired level. However, I think that the sensitivity of public institutions on this issue and the new construction projects implemented will increase the public’s interest and awareness in this field.

“Concrete alone is responsible for 5 percent of global carbon emissions”

- What will be the contribution to the world, humanity and nature if a building is constructed using wood instead of concrete?

When you compare concrete and wood, we can see that these structures have returns both in terms of earthquake safety and their impact on nature. From an earthquake point of view, it would not be right to say, “Make your building out of wood, it is much more durable compared to concrete”. Because whether you build a building in wood or concrete, both types of structures can be durable as long as the relevant static calculations and standards are adhered to. However, some nuances come into play here. For example, in high-rise buildings, wood provides an advantage as it is a lighter material. With its flexible structure, wood can better adapt to long displacements and oscillations. Also, in the event of a collapse, wooden structures do not form heavy piles like concrete. Because wooden structures are lighter, they allow people to reach them faster after demolition. This is one of the key advantages of wood.

In terms of nature, the Green Deal has emerged to combat climate change. There are commitments such as halving carbon emissions by 2030 and a zero carbon target by 2050. Türkiye is also a party to these commitments. In this context, reducing carbon footprint is of great importance. Carbon markets are now established in the world. If your carbon footprint is high and you do not have efforts to tolerate it, you have to pay a carbon tax. Therefore, as in every sector, the materials used in the construction sector must be selected and produced correctly. When we look at the construction sector, we see that the material with the largest share in carbon emissions is concrete. Concrete alone is responsible for about 5 percent of carbon emissions worldwide. This is a very serious figure. The environmental impact of concrete is evaluated not only during the production process but also throughout its entire life cycle. From the initial production stage to the final product, concrete has a very high carbon footprint in terms of energy consumption, waste management, reuse and recycling opportunities. Wood, on the other hand, provides a great advantage in this respect. By its very nature, it is a material that sequesters carbon, emits no carbon emissions and has a zero carbon footprint. Therefore, in line with nature conservation goals, wood stands out as the most suitable building material among the alternatives.

- How is the necessary raw material source provided?

Now, this situation arises; “Is there such a resource? Aren’t we cutting down trees? Aren’t we destroying nature in this case?” One of the most critical points for OGM to initiate this study is to find solutions to these questions. Each year, General Directorate of Forestry determines which trees will be cut down and how this process will be carried out. Targets are set for the trees to be cut, these targets are approved and put into practice. In addition, the cutting of trees and the distribution of raw materials are carried out regularly every year in accordance with these targets. What does this mean? OGM regularly determines and manages the proportion of usable forests each year. This process provides the raw material source necessary for a sustainable wood construction industry. The sustainability and adequacy of these resources are clearly stated in OGM’s own reports. So, “Why are trees cut down? Can they not be cut down and remain permanently?”, this situation also creates a disadvantage. Because growing trees can interfere with the need for both nutrients and light for new trees. This negatively affects the healthy and balanced growth of forests. In addition, when uncut trees start to decompose in the forest, they start to emit the carbon they have stored as emissions into the atmosphere. This poses an ecological threat.

“We can build our high-rise buildings with innovative structural wood materials that can be produced entirely with domestic resources”

- Can you tell us about the TUBITAK project you realized at the university? And what do the results of this project show us? How can we draw a road map for the future?

The TUBITAK project is our most recent project. However, we have carried out eight TUBITAK projects related to structural wood materials and CLT, but these projects are only now attracting attention as the level of awareness is just beginning to be raised. The aim of this project was to develop a new structural wood material that is energy efficient and earthquake resistant. We called this material a self-insulating building material. A building material developed in this way had not been developed in Türkiye before. We designed a 1 by 2 scale, 2-storey infrastructure with this material and performed earthquake tests. This structure was tested on a shaking table as a structure produced with CLT for the first time in Türkiye. During the test, this structure was subjected to a force higher than the gravitational force generated in the Kahramanmaraş earthquake. Structurally, there was no damage to the CLT material, only minor damage to the connection points. The structure survived completely and was preserved in an easily dismantled and reassembled position. This study has shown us that we can design and build our own high-rise buildings thanks to innovative structural wood materials that can be produced entirely with domestic resources. In risky areas, including earthquake zones, this material can now be easily used in institutions such as schools and hospitals as well as residences, thanks to its advantages such as fast construction, earthquake resistance, natural and healthy properties.