Solid panel, which is becoming increasingly widespread, especially in the furniture and decoration sector, continues to maintain its place and importance as a special material in Türkiye, thanks to its advantages over other panel products. This development in the Turkish solid panel industry, whose growth has accelerated in the last 10 years and increased its production capacity every year, has also been the biggest driving force of solid panel furniture machines. The products offered to the market by the Turkish solid panel machinery industry, where export figures have been on an upward trend in the last 10 years, are closely followed by the whole world.

Solid wood is the solid and pure form of the raw log formed after the tree is cut, without shaping. Solid wood, which has a durable structure because it consists of a single piece of wood, is obtained from different tree species. Products made from this natural wood material can be used for up to 200 years on average, thanks to their durable structure. Solid panel, on the other hand, is defined as boards obtained by gluing small-section solid wood pieces of the same tree species, that is, lamellae, as a single piece or as a piece joined end to end, in a single layer from the edges to each other in longitudinal and transverse directions, especially with the fibers parallel.

Solid panel continues to maintain its place and importance

Solid panels produced in this way are showing a remarkable development in Türkiye as well as in the world. The use of solid panels in Türkiye is increasing due to both the advantages of solid wood material over other materials and its features that meet all kinds of requirements with its high size and surface stability. Solid panel, which finds more widespread use day by day, especially in the furniture production and decoration sector, continues to maintain its place and importance as a special material with its superiority over other panel products.

Solid panel supports employment with rapidly increasing production capacity

The trend towards wooden boards has increased significantly in the last 10 years in order to meet the product diversity and high demand in parallel with the technological and economic developments in the world. The absence of problems such as moisture differences encountered in solid wood materials and physical, mechanical and technological properties that vary depending on the defects of the material is an important reason for choosing wooden board products. Both the production speed of solid wood and the difficulties in the application of the resulting product have led manufacturers focusing on the panel industry to produce solid panels. On the other hand, in addition to the rising standard of living in the world, increasing consumer awareness and ecological approaches have also been an important factor in expanding the area of usage of solid panel in the furniture and woodworking industry. For this reason, solid panel has become a sector that contributes to employment by increasing significant capacity in the world and in our country.

Approximately 10 times lower investment costs

It is possible to use solid panel in almost every field where other boards such as chipboard, MDF and plywood are used in the forest industry. The warmth of wood and the fact that it is a completely natural material are the most important advantages of this product. This ensures long-lasting and safe use, especially indoors. On the other hand, solid panel can be produced with approximately 10 times lower investment costs compared to MDF and chipboard facilities. This has enabled the investments made in this material to increase rapidly in the last 10 years. This product has created a great benefit in bringing solid wood back to its deserved place in the forest industry. Thus, it became possible to directly use the natural features and warmth of solid wood in the rapidly changing furniture industry. In this sense, we can consider the solid panel as the shining star of the forest industry sector.

We see that home and garden furniture leads the way in solid panel furniture production. The highest demand in the sector is for sofa sets, dining room furniture and office furniture, which are classified under home and garden furniture. At this point, we see that home and garden furniture takes the lead in solid panel furniture production.

Automation systems make Turkish machines more attractive in the world market

The importance given to R&D investments and innovation lies behind the success of the Turkish woodworking machinery industry. Domestic manufacturers constantly follow technological developments and integrate these technologies into their products in order to meet and even exceed international standards. This effort leads to the introduction of more efficient, durable and easy-to-use machines. Advances in automation systems and environmentally friendly production techniques make Turkish machines attractive in the world market. In addition, manufacturers’ customer-oriented approach, excellence in after-sales services and training programs increase customer satisfaction and reinforce reliability in the sector.

Managed to achieve a strong position in the global arena with high quality products

When Türkiye’s export and import data of the last two years for the machine types in the solid panel machinery group are examined, it is seen that the country exports the most machines in the others group, with 47 million dollars in 2022 and 55 million dollars in 2023. Sawing machines come in second place with an annual export figure of 35 million dollars. The export of machines in the others group corresponds to approximately 56 percent of the total exports of 2022 and 73 percent of the total exports of 2023. Continuously increasing its exports in the field of solid panel machinery, Türkiye has managed to gain a strong position in the global arena with its competitive prices and high quality products. The decrease in import rates also shows the success of domestic production and the ability of Turkish machinery manufacturers to produce at world standards.

Areas of use diversify every year

The areas of usage of solid panels, which were used by staircase manufacturers in Türkiye 15-20 years ago for step manufacturing, have expanded considerably today. Solid panel, which is a material that meets all the needs of manufacturers and users among wood-based materials with its features, is preferred in many different sectors and products. On the other hand, solid wood products, which are easily used in all kitchen and bedroom furniture designs, whether classical or modern, offer a warm and aesthetic appearance and natural and comfortable use to these areas. While many different designs can be created with techniques such as carving, drilling and inlay, it becomes an indispensable product for kitchens and bedrooms with its long-lasting and durable structure. Solid panels, which maintain their natural features even when used as an industrial product, are also used extensively in environments and products where health and hygiene are required. Solid panel, which is naturally resistant to bacterial and fungal growth and does not contain any industrial pests, is especially preferred in children’s room furniture and toys. In addition, due to these features, schools also prefer wood. Solid panel products are gaining ground in school desks and other school furniture. Solid panel products, which are used in almost every area of gyms, are frequently preferred in both flooring and column/beam coverings. It is possible to see wood in all sports fields because it protects against impacts and regulates the natural living conditions of the environment.

Exports, which were 55 million dollars in 2015, increased to 133 million dollars in 2023

The regular increase in the areas of usage and annual production capacity of solid panel every year is a great driving force for solid panel furniture machines. Turkish woodworking machinery manufacturers, who provide solutions that meet the needs of the market by achieving high quality standards in the production of solid panel machines, support the continuous increase in export figures. Turkish solid panel machines, whose annual production figures are estimated to be 300-350 million dollars, are in great demand, especially in the European, Asian, American and Middle Eastern markets. In Turkish solid panel furniture machines, exports of 55 million dollars and imports of 200 million dollars were made in 2015, however, today we see that the export and import rates have completely changed places. Exports of solid panel furniture machines amounted to 119 million dollars in 2022, and imports amounted to 66 million dollars. In 2023, exports amounted to 133 million dollars and imports amounted to 85 million dollars. This increase in export figures also proves the technological superiority and reliability of Turkish machines.

AES Group

Drilling machines offer a quick solution for manufacturers

AES Group has been operating in the woodworking industry since 2001. As of 2024, we continue production in 6 different facilities in an indoor area of 40 thousand square meters in total. We strive to offer the fastest and most accurate solutions to our customers with the services we have been providing for more than 20 years and the production infrastructure we have developed. For this reason, we produce solutions to customer needs and expectations with 34 personnel in the largest R&D center of our sector. International markets constitute 60-65 percent of our company’s sales volume. In this regard, in order to increase our service speed and quality, we have branches providing sales and after-sales services in Canada, England, Belgium and France, including 2 in the USA. We have 5 main production groups in the AES machinery park: nesting machine and console table group, sizing group, hole group and edge banding group. I have to mention our flat table machines. With our Raptor Ultra model at the forefront, which is famous all over the world; Extreme Ultra, Super Nova and Flexa Pro are the 4 different models we offer. In these models with flexible production capabilities, we offer solutions from the entry level to the fully automatic industrial production line. The drilling machine group is one of the machine groups with a wide product range in our company. We offer 4, 5 and 6 surface treatment options on our Sirius, Go! and Go! Ultra drilling machines. Our Go and Go Ultra machines are produced with the industry 4.0 base and contain an automatic production line solution. Drilling machines, which can work in combination with nesting machines, offer a quick solution for manufacturers. As AES, we work to make this process more effective and faster by ensuring that all our machines communicate with each other. Our company, which has been producing value since the day it was founded, continues to grow with the aim of becoming your global partner.

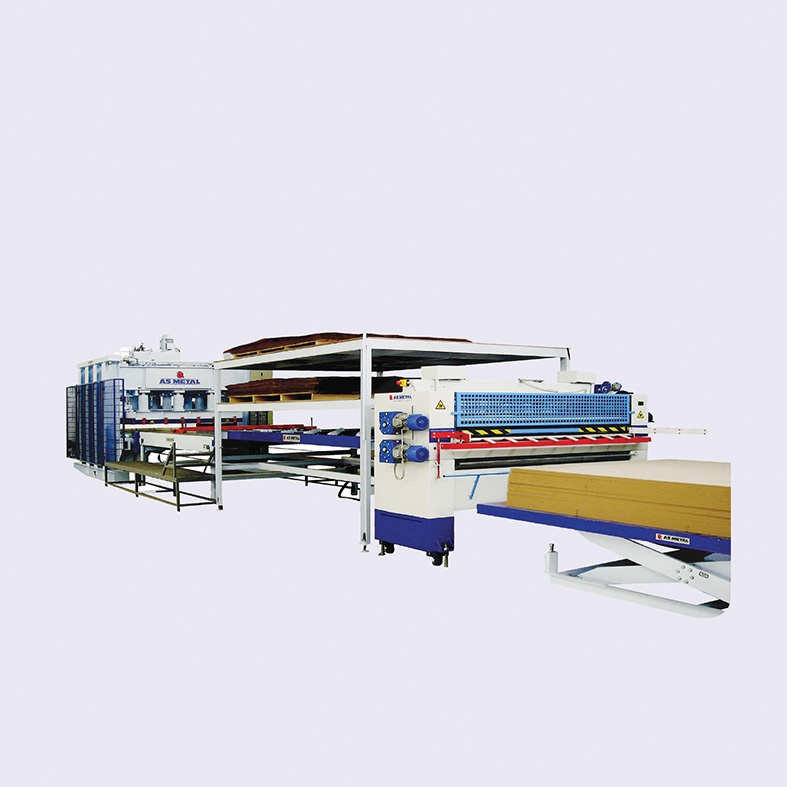

As Metal Machinery

Quality, operating performance, efficiency

Our company, whose foundations were laid in 1968 and has been providing uninterrupted service in the machinery industry since then, has always attached great importance to the principles of quality, operating performance and efficiency. As a result of the developments in the machinery sector in the 90s, we, As Metal, turned especially to the woodworking machinery sector and started to produce hydraulic machinery. Nowadays, we mainly produce hydraulic presses and other cutting-sawing machines. Press machines belonging to the As Metal brand are generally used in panel manufacturing. Our machines are used especially for printing natural coating on materials such as chipboard and MDF, or foils and laminate materials created with the recently developing technologies. Our press machines, which offer manual and automatic operation, are produced with different types of plates and heating systems according to need. Our state-of-the-art machines save energy. For the last 6-7 years, as As Metal, we have also focused on the production process of long laminated beams for the manufacture of massive beams and columns. These automatic pressing lines designed for solid wood lamination are suitable for the manufacture of wooden beams and panels. It can be produced with either a hot platen or high frequency heating as well as a cold platen as a drying system. Ideal for the production of solid panels, laminated window frames and CLT (Cross Laminated Timber) wooden walls, this system works fully automatically and can respond to large production capacities with its high performance.

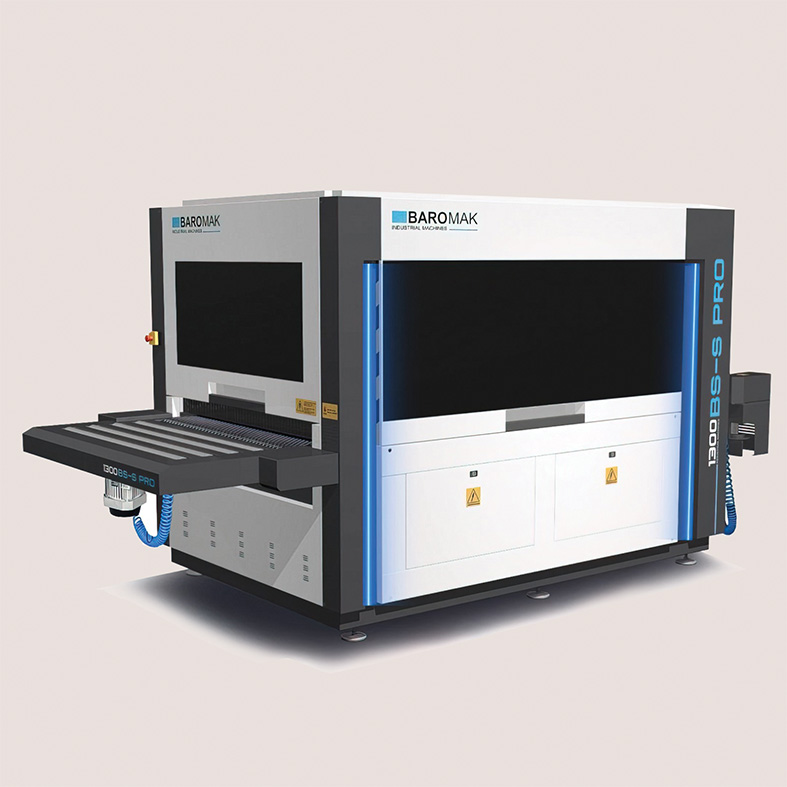

Baromak Machinery

Innovative solutions and high quality standards in sanding and spraying machines

As Baromak Machinery, we experience the pride of being the leader in the Turkish woodworking machinery sector, offering innovative solutions and high-quality standards in sanding and spraying machines. With years of experience and a commitment to continuous improvement, we strengthen our position in the industry day by day. We have a wide range of products tailored to meet our customers’ needs, including brush sanding machines, spraying machines, anti-static dust collection machines, and side sanding machines. Each machine is manufactured to exceed industry standards in quality and durability. As Baromak Machinery, we are excited to introduce our new wide belt sander and wiring machines to our customers, embodying our vision of constant development and innovation. By investing in new technologies, maintaining the highest levels of customer satisfaction, and committing to environmentally-friendly production, we aim to further solidify our position in the global market. These goals and our successes highlight the strength and potential of the Turkish woodworking machinery sector.

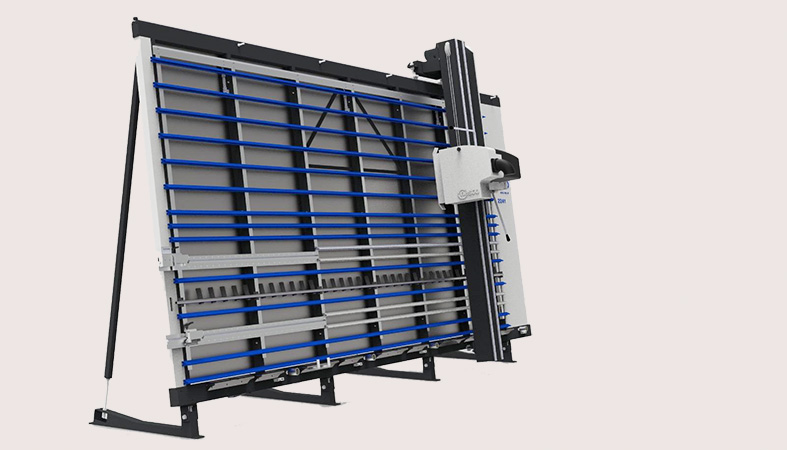

Nesto Machine

High performance, ease of use and occupational safety

As Nesto Machine, we are proud to introduce our vertical panel sizing machine equipped with the latest technologies for the furniture and woodworking industry. This machine, which we produce in Türkiye, makes a difference in the sector in terms of high performance, ease of use and occupational safety. Our vertical panel sizing machine is designed for precise and fast cutting of large-sized wooden panels. Thanks to its compact and ergonomic structure, it allows you to get maximum efficiency from your workshop area. Our machine can cut all kinds of wooden panels to the desired dimensions with its powerful engine and sharp and durable blades. With its user-friendly control panel, it allows operators to start work quickly and manage the cutting process easily. Equipped with advanced safety features, our machine helps prevent accidents by prioritizing the safety of users. It improves the flow of your production line with its precise cutting capacity and high speed performance. At the same time, it reduces your operating costs with energy efficiency and low maintenance requirements. We invite all industry professionals who want to see this innovative machine more closely and get detailed information, to our stand at the WoodTech Fair, which will be held in İstanbul between October 12-16, 2024. At the fair, you can meet our expert team, watch live demos of our machine and discover the benefits it can provide to your business.

UVTEK Group

Latest technology in painting 3D surfaces

As UVTEK Group, we use our more than 30 years of knowledge, wisdom and experience in finishing systems in the development of alternative solutions in the wood, glass and printing & packaging sectors. Our company produces MDF surface paint and pattern printing and UV high gloss lacquer lines, edge band pattern printing machines, spray painting and parquet polishing lines for the furniture industry, for leading companies in the sector at home and abroad; under the ACCEMA brand being its innovative face. We also produce roller coater painting machines and drying ovens, UV drying systems, curtain coating, automatic spray painting and brush sanding machines used in these lines. UVTEK Group has added the newly developed robot spray machine to its product range, using the latest technology in painting 3D surfaces under the ACCEMA brand. With a specially developed image processing system, the area to be painted is defined and transferred to the painting robot. Thus, perfect painting is achieved with perfect hand movement ability. UVTEK also introduced the UV Excimer device to the market for matte surfaces, which has become a trend in the world in recent years in drying systems. The Excimer device initiates a polymerization process at the top of the UV coating layer. In this way, a micro-folded structure is created and a perfect matte or soft touch surface appearance is achieved.

Üstünkarlı Machinery

Designed for cutting multiple pieces of wood

In the sawmilling industry, optimizing cutting and processing operations is crucial for enhancing productivity, reducing costs, and maximizing the quality of finished products. One modern piece of equipment that meets these requirements is the multiriple ripsaw with Canter and scanning. The multiriple ripsaw is designed to cut multiple pieces of wood simultaneously. Equipped with multiple saw blades on two shafts, it enables faster production and better utilization of raw material compared to traditional cutting methods. The canters integrated into the multiriple ripsaw prepare the wood by removing slabs and irregularities before the saw blades make the final cuts. This ensures a clean and precise cutting surface, reducing defects and enhancing the quality of finished products. A cleaner cut also means less waste and higher added value for each piece of processed wood. One of the major advantages of this solution is its ability to optimize the use of raw wood. Canters remove unusable parts of the wood before cutting, maximizing the yield of usable finished products. Additionally, precise and multiple cuts minimize material losses, resulting in significant waste reduction. This machine offers great flexibility in terms of cutting dimensions. It can be adjusted to produce different widths and thicknesses of wood according to the specific needs of the sawmill and customer orders.